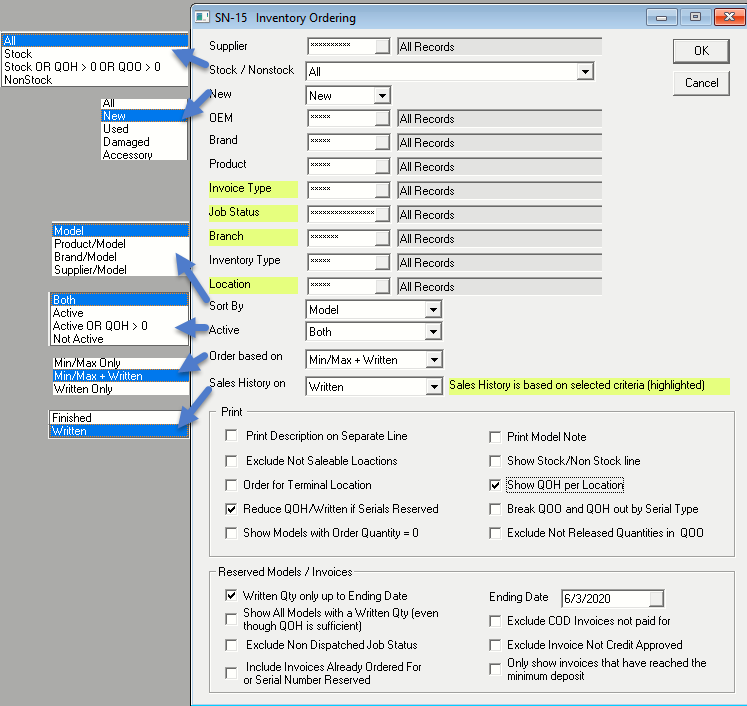

SN-15 Inventory Ordering

This report is primarily used by companies who look at sales trends so they can fulfill min/max ordering. This report also has an option to fulfill backorder quantities and has the same capabilities as OE-04 Written Models report.

Report Parameters

-

Supplier: This option will let you select one or multiple suppliers.

-

Stock/Non-stock: This option will let you select Stock, Stock OR QOH > 0 OR QOO > 0 (Select all models that are Stock, or any model (Stock/Non-stock) where QOH is greater than 0, or QOO is greater than 0), Non-stock or All (Stock & Non-stock Models). It defaults to All.

-

New: This option will let you select the model level. Options are All, New, Used, Damaged, and Accessory. It defaults to All and other options are not commonly used.

-

OEM: This option will let you select one or multiple OEMs (Original Equipment Manufacturer). The OEM is used to define groups of brands. If one buyer is responsible for a handful of brands, you can create an OEM in the OEM Table and then assign the OEM to each brand. This way one single OEM of ‘WP’ can pull Maytag, Jenn air, and Whirlpool etc.

-

Brand: This option will let you select one or multiple brands.

-

Product: This option will let you select one or multiple products.

-

Invoice Type: This option will let you select one or multiple invoice types.

-

Job Status: This option will let you select one or multiple job statuses. Some companies will only order product once it is in ‘Scheduled’ status. The job status allows you to define if you can select this job status only once the minimum deposit has been reached and if the job status is dispatched.

-

Branch: This option will let you select one or multiple branches. Access to this is based on security.

-

Inventory Type: This option will let you select one or multiple inventory types. The inventory type is used to define inventory. I.E. Appliance, Electronics, Furniture, Mattress etc. If one buyer is responsible for electronics inventory types, then you can create inventory types in Inventory Types Table and then assign the inventory type to each model. This way the user responsible for ordering electronics would run for inventory type electronics and it will grab all the models that belong to that inventory type.

-

Location: This option will let you select one or multiple model locations. I.E. The model location on invoice detail. This is useful if you are only ordering for specific locations or regions.

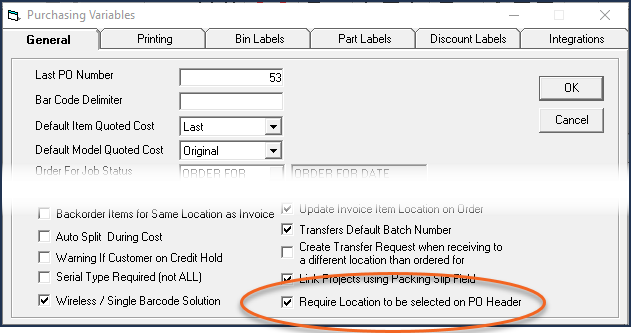

infoSelecting a Location is optional, unless the Require Location to be Selected on PO Header option is active in Purchasing Variables (Tools > System Maintenance > Variables > Purchasing > General tab). If this option is active, a Location must be selected from the dropdown list.

-

Sort By: Report can be sorted in different ways:

- Model

- Product/Model

- Brand/Model

- Supplier/Model

-

Active: This option will let you select Active, Active or QOH > 0, Inactive Models or Both (Active and Inactive Models). It defaults to Both.

-

Order based on: This option will let you fulfill min/max quantity, and/or written quantity. I.E. It is a not shipped model line on invoices or both min/max and written quantity. It defaults to last used.

- Min/Max Only: This option will only look at Min/Max quantity & not Written quantity.

- Min/Max + Written: This option will look at both Min/Max quantity and Written quantity.

- Written Only: This option will only look at Written quantity and not Min/Max quantity.

-

Sales History on: Options are finished or written. I.E. This option will let you see the sales history on the report based on either finished/delivered sales or written sales.

-

Print Description on Separate Line: If this option is checked, it will print the full model description on a separate line.

-

Exclude Not Saleable Locations: If this option is checked then it will exclude locations flagged as not saleable in Tools > System Maintenance > Tables > Locations.

-

Order from Terminal Location: If this option is checked when the purchase order is written, it will populate the location on the model line in the purchase order from the Model Delivery location set in File > Terminal Settings. If unchecked, it will order the product based on the location on the model line in invoice detail. This option is commonly selected where inventory is received into multiple locations so the ordering person’s terminal settings will be set to where the product is expected to arrive. This is also connected to the Interstore Transfer system so EPASS can coordinate movement of product when it arrives in a different location than it needs to be delivered from.

-

Reduce QOH/Written if Serials Reserved: If this option is checked then it will reduce the QOH and written quantity shown on the report if a serial number is reserved to an invoice. I.E. If QOH = 1 and Written = 1 but the written invoice has reserved the serial number that is on hand, it will reduce the QOH to zero because the one on hand is reserved. It will also reduce the written to zero because the one that is written has a serial already reserved to it so we do not need to order one for that invoice.

-

Show Models with Order Quantity = 0: If this option is checked then it will show models that do not need to be ordered. It will include models where EPASS has calculated that zero need to be ordered either based on the min/max and/or written depending upon the options chosen on the report selection.

-

Print Model Note: If this box is checked then it will print the model note from Serial Inventory > Maintenance on the report. This is particularly useful when you can import helpful information such as long description, sales price information, future IRs etc. from the price list templates.

-

Show Stock/Non-Stock Line: If this option is checked then it will show if the model is stock or non-stock on the report.

-

Show QOH per Location: If this option is checked then it will break out the QOH per location.

-

Break QOO and QOH out by Serial Type: If this box is checked then it will print QOO and QOH by serial type. Only select this if you use serial type to separate your builder, retail, and clearance inventory as then it is beneficial to breakout both the QOO and the QOH by serial type.

-

Exclude not released quantities from QOO: If this box is checked then it will exclude purchase orders that are “not released” from the QOO. I.E. If you use releasing on purchase orders then you probably do not want to include purchase orders that have not been released in your QOO since those are not coming in yet.

-

Written Qty only up to Ending Date: If this box is checked then the written quantity on the report will only include invoices scheduled for pickup or delivery up to the ending date. If this box is not checked, the written quantity shown on the report will be for all product regardless of when it is being picked up or delivered.

-

Ending Date: This is the cut off for the invoice schedule date and invoice pickup date. It will show you everything that is being delivered or picked up to this date.

-

Show All Models with a Written Qty (even though QOH is sufficient): If this option is checked it will show all the models with written quantity regardless of the QOH.

-

Exclude Non Dispatched Job Status: If this option is checked then it will exclude non-dispatched job statuses set on the invoice. I.E. Meaning Do Not Dispatch is checked in System Maintenance > Table > Job Status Table. Most companies will want to see estimated dates on the report and then check with the sales staff to see if the date is good or not and other companies place the responsibility on the salesperson to update their invoices properly or else product will not be brought in.

-

Include Invoices Already Ordered For or Serial Number Reserved: If this option is checked then it will include invoices already ordered for or that already have a serial number reserved.

-

Exclude COD Invoices not paid for: If this option is checked then it will exclude COD invoices not paid in full. Most companies have policies that they will not order product until it is paid in full. If you wish to do this and are going to be strict about the policy, then this option is good for you. This goes back to putting the responsibility on the salesperson.

-

Exclude Invoices Not Credit Approved: If this box is checked then it will exclude “Not Credit Approved” invoices. See Credit Approval Process.

-

Only Show Invoices that have reached the minimum deposit: If this box is checked then it will only show invoices that have reached the minimum deposit. I.E. If you have a minimum deposit rule in place, which is set on each invoice type, then do you only want to see invoices that have reached that minimum? This is similar to excluding COD invoices not paid for.

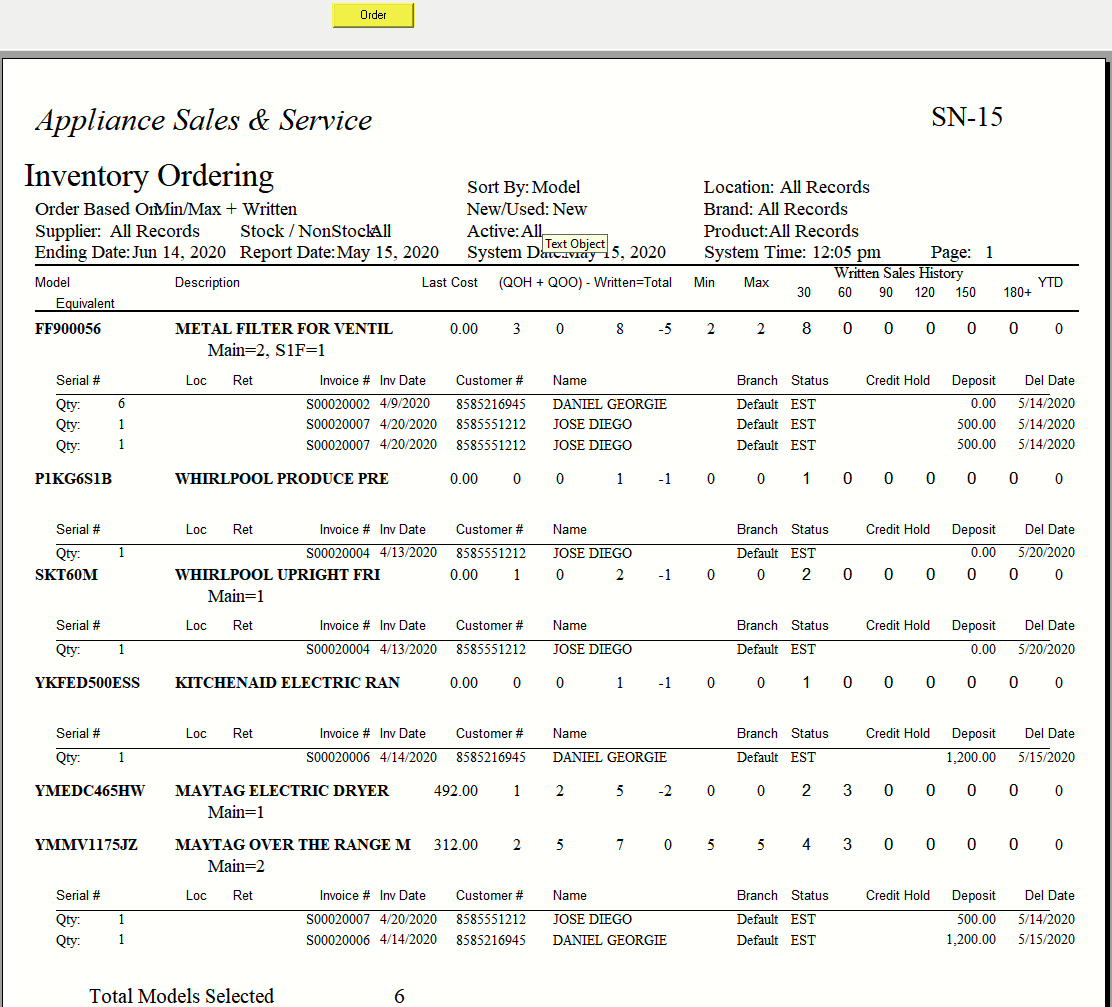

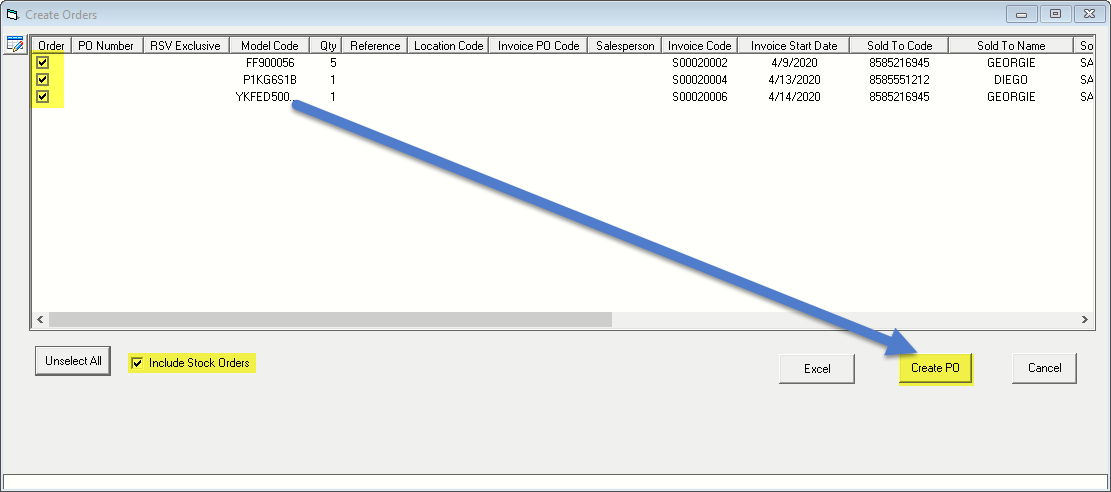

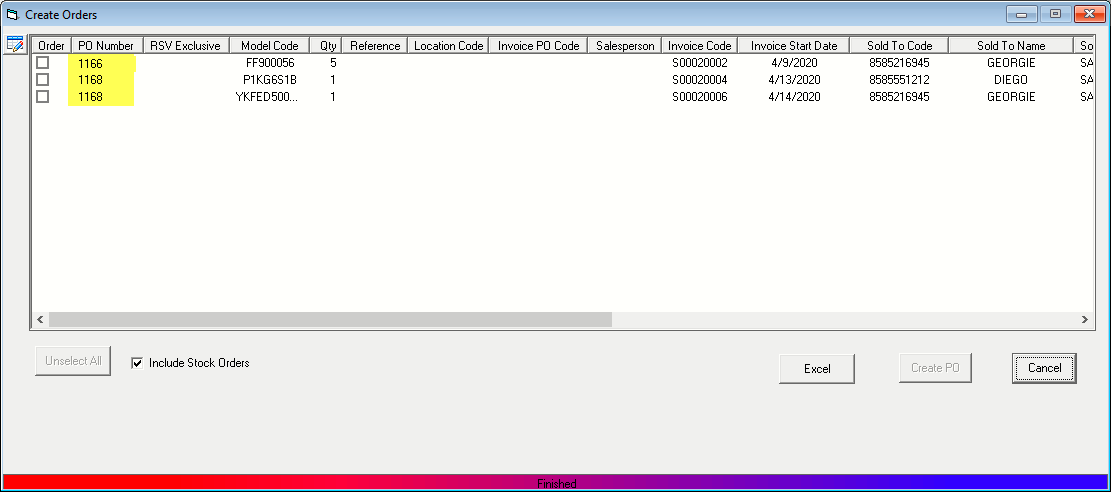

At the top of the report, there is an Order button. Once you click on Order it will open the “Create Orders” window (see below) where it will show each model with a written quantity.

If Include Stock Orders is checked, then it will show models that need to be ordered based on the min/max quantity. Select the models you want to order and then click on Create PO to create the PO.

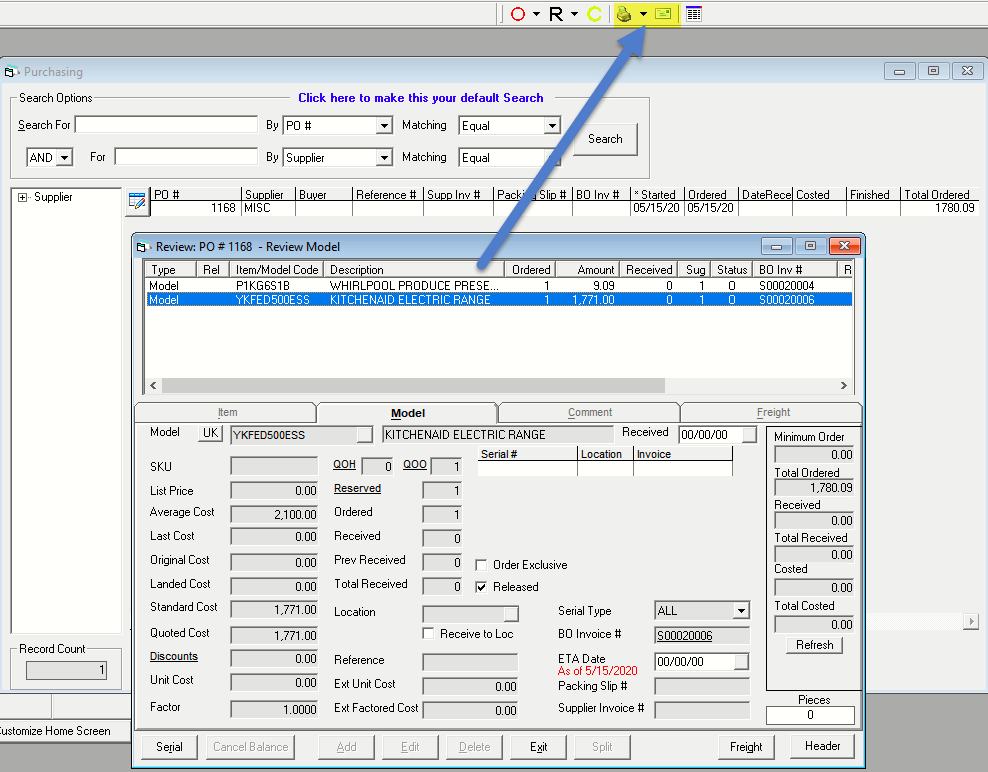

Clicking on the Create PO button will generate the PO. After EPASS has created the PO, you’ll notice the report refreshes and now it displays the list of POs that were automatically created.

Once the PO number is generated, either copy the PO# from the report and paste it into Purchasing > Maintenance or use Purchasing > Find POs to find the PO number then either print, email or use the Purchasing > PO Export function to send the PO to the vendor.

May 21, 2025